prev

next

-

All products

-

Filters

-

Plate filters

- Sheet filters

- Sheet filters for fruit juices

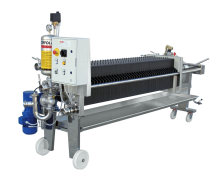

- Industrial plate filter press

- Plate Filter Univer

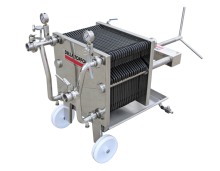

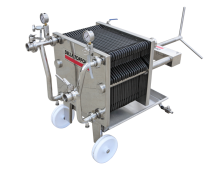

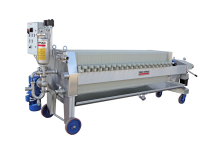

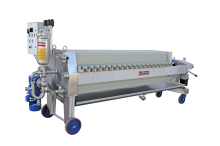

Della Toffola’s UNIVER filters enable the use of both filtering sheets and hollow plastic filtering plates. They are based on a tried and tested technology that Della Toffola has been applying for decades, and have always been a simple and effective solution for all the processes that involve separating the liquid phase from the solids in suspension.

Della Toffola’s UNIVER filters enable the use of both filtering sheets and hollow plastic filtering plates. They are based on a tried and tested technology that Della Toffola has been applying for decades, and have always been a simple and effective solution for all the processes that involve separating the liquid phase from the solids in suspension. - Filter presses with plates for fruit juices Show all

Plate filters

-

Cross-flow filters with ceramic membranes

Cross-flow filters with ceramic membranes

-

Cross flow filters with organic membranes

Cross flow filters with organic membranes

-

Horizontal discs kieselgur filters

Horizontal discs kieselgur filters

-

Rotary vacuum filters

Rotary vacuum filters

-

Housing for microfiltering

Housing for microfiltering

Show all

Filters

-

Plate filters

- Filling systems

- Presses

-

Reverse osmosis

- MOVIRO reverse osmosis systems for wine Show all

Reverse osmosis

- Flotation units

-

Destemmers-crushers and crushers

- MACERATION ACCELERATOR DTMA

- NDC Crusher Destemmer Show all

Destemmers-crushers and crushers

-

Liquids and solids handling

-

Pumps

Pumps

-

Grape receiving

Grape receiving

-

Grape sorting and handling

Grape sorting and handling

Show all

Liquids and solids handling

-

Pumps

-

Heat exchangers

- Plate/tubular heat exchangers Show all

Heat exchangers

- Refrigerating systems

-

Stabilization systems

- Polarsystem

- DT stabilization

- DTX resine skids for wine stabilization Show all

Stabilization systems

-

Thermovinification plants

- Biothermo

- Biothermo Cooler thermovinification system Show all

Thermovinification plants

-

Tanks, pressure tanks and fermentation tanks

- Vertical red winemaking tanks SELECOMPACT

- Storage tanks for CSD

-

Vertical fermentation tanks

Vertical fermentation tanks enable a traditional vinification process with cap sprinkling by means of a centrifugal or motorized sprinkler and pumping over with a stainless steel screw pump with a rubber impeller that ensures a gentle displacement of the must and an effective extraction of anthocyanins, tannins and aromatic substances.

Vertical fermentation tanks enable a traditional vinification process with cap sprinkling by means of a centrifugal or motorized sprinkler and pumping over with a stainless steel screw pump with a rubber impeller that ensures a gentle displacement of the must and an effective extraction of anthocyanins, tannins and aromatic substances. - Horizontal fermentation tanks

- Vertical red winemaking tanks SELECTOR

- Inox tanks for wine

- Carbon steel and stainless steel pressure tank

- Beer storage tanks

- Beer fermentation tanks

- Fermentation tanks for cider

- Storage tanks for cider

-

Tanks for storing fruit juice

The tanks for storing fruit juices are suitable for containing the juice under atmospheric pressure to preserve its organoleptic features. The juice is stored at a temperature of 8-10°C, thanks to a special hollow space in the cylinder of the tank through which a low-temperature glycol solution circulates. The tanks are also complete with a system for the controlled delivery of nitrogen.

The tanks for storing fruit juices are suitable for containing the juice under atmospheric pressure to preserve its organoleptic features. The juice is stored at a temperature of 8-10°C, thanks to a special hollow space in the cylinder of the tank through which a low-temperature glycol solution circulates. The tanks are also complete with a system for the controlled delivery of nitrogen. - Stainless steel milk tank Show all

Tanks, pressure tanks and fermentation tanks

-

Rinsers and sterilizers

- Rinsers

- Rinsers/Blowing machines

- Sterilisers Show all

Rinsers and sterilizers

- Capping machines

-

Packaging machines

- Depalletisers - palletisers

- Cardboard box forming - Closing machine

- Unpacking - packing machines

- ISOLA 700 monoblock

-

Shrink-wrapping machines

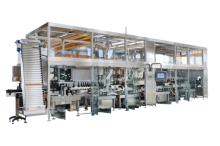

The shrink-wrapping machines are automatic lines for packing with thermoshrinking film are designed and manufactured in different models, according to the type of container, to the type of package (without any carton support, with lap or with tray) and according to the production capacity of the line.

Show all

The shrink-wrapping machines are automatic lines for packing with thermoshrinking film are designed and manufactured in different models, according to the type of container, to the type of package (without any carton support, with lap or with tray) and according to the production capacity of the line.

Show all

Packaging machines

-

Labelling machines

-

Labelling machines up to 6.000 bph

Labelling machines up to 6.000 bph

-

Labelling machines over 6.000 bph

Labelling machines over 6.000 bph

Show all

Labelling machines

-

Labelling machines up to 6.000 bph

-

Premix plants and carbonators

- Cider premix systems

- CSD premix systems

- Water carbonation systems Show all

Premix plants and carbonators

- Pasteurizers

- CIP plants

-

Complete plants

- Complete enological systems for wineries

- Complete systems for making cider from concentrate

- Industrial apple cider making equipment

- Complete systems for the production of fruit juices

- Syrup rooms

- Mineral Water Equipments

- Mini dairies

-

Systems for producing milk for drinking

Priamo produces systems for the production of milk for drinking. These systems can be customized to suit the needs of a given client, who is followed up from the design stage right up to the completion and commissioning of the system, which can have a production capacity ranging from 400 to 1,000 l/h.

Show all

Priamo produces systems for the production of milk for drinking. These systems can be customized to suit the needs of a given client, who is followed up from the design stage right up to the completion and commissioning of the system, which can have a production capacity ranging from 400 to 1,000 l/h.

Show all

Complete plants

-

Mini-dairy products and machines

- Cradle vat for ricotta coagulation

- Pumps for dairy sector

- Multipurpose mini coagulation vats

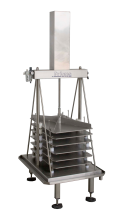

- Mini vertical press for cheese and ricotta

-

Yogurt production lines

These pre-installed automatic systems for the production of yoghurt are used with a set of recipes to enable the milk to be pasteurized and kept at the incubation temperature, and then the yogurt is allowed to mature for a preset time, then cooled and whipped for the amounts of time and at the rates established in the operator’s recipe.

These pre-installed automatic systems for the production of yoghurt are used with a set of recipes to enable the milk to be pasteurized and kept at the incubation temperature, and then the yogurt is allowed to mature for a preset time, then cooled and whipped for the amounts of time and at the rates established in the operator’s recipe. - Yogurt carton fillers

- Steam generators Show all

Mini-dairy products and machines

-

Dairy products and machines

-

Milk receiving

Milk receiving

-

Milk heat treatments

Milk heat treatments

-

Curd coagulation and treatment

Curd coagulation and treatment

-

Ricotta production equipment

Ricotta production equipment

-

Milk fermentation units

Milk fermentation units

-

Presses and milk salting

Presses and milk salting

Show all

Dairy products and machines

-

Milk receiving

-

Water treatment plants

- Chemical-physical treatment plants

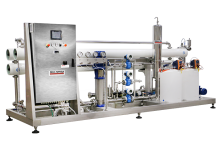

- Reverse osmosis for industrial processes or for the industrial production of soft drinks, mineral water and beer

- Reverse osmosis with remineralization

-

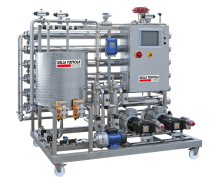

Organic ultrafiltration for water bottling lines

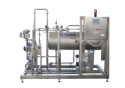

Organic ultrafiltering lines suitable for use in pretreatment processes, in the production of drinking water, in mineral water bottling lines, and to prepare water for use in the production of soft drinks and other beverages. Plug-&-play systems for interfacing with the pre- and post-sections, made of stainless steel (apart from the vessel membranes), automatically operated.

Organic ultrafiltering lines suitable for use in pretreatment processes, in the production of drinking water, in mineral water bottling lines, and to prepare water for use in the production of soft drinks and other beverages. Plug-&-play systems for interfacing with the pre- and post-sections, made of stainless steel (apart from the vessel membranes), automatically operated. - Nanofiltration

- Ceramic ultrafiltration (UF) for treating oily emulsions

- Biological systems

- Microfiltering systems using ceramic and organic membranes

- Filtering (with sand or carbon) Show all

Water treatment plants

All products

-

Filters

- Find a product

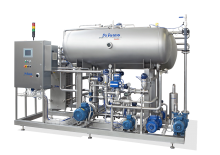

Water treatment

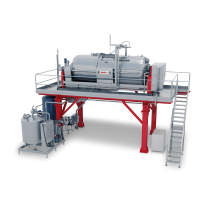

Della Toffola supplies industrial water treatment equipment based on a precise, specific philosophy comprising the following essential steps: approaching the application, analyzing the application, collecting information and conducting a feasibility study, developing the process, design, installation and start-up, and operator training.

To see our references CLICK HERE

Some of the sectors of interest:

Agro-food industries, food preserving industries, manufacturers of soft drinks and mineral water, distilleries, beer and cider breweries, wineries, dairies and the milk and cheese industry, ceramics and sanitation industries, chemical and pharmaceutical industries, car and related component manufacturers, foundries, steelworks, electronic industries, electrical energy production plants , petrochemical industries, textile industries and tanneries, etc.

Water treatment equipment and systems are produced for:

- making water drinkable

- preparing water for bottling

- preparing water for the production of soft drinks, fruit juices, beer, etc.

- treating wastewater for all sorts of civil and industrial purposes

- sludge dehydrating stations

Della Toffola also designs and implements the revamping of existing industrial water treatment plants to adapt them to new functional or dimensional needs, which includes updating the technology involved and/or increasing their output.

The sections comprising the system are developed on the grounds of a dedicated, detailed project, then constructed and assembled at the company's plant. In addition to supplying the technology and systems, Della Toffola also provides its customers with a complete service that includes the preliminary feasibility study, installation and start-up, thorough training of the customer’s personnel, and the supply of all necessary documentation and certificates, as well as after-sales support and servicing.

To see our references CLICK HERE

Some of the sectors of interest:

Agro-food industries, food preserving industries, manufacturers of soft drinks and mineral water, distilleries, beer and cider breweries, wineries, dairies and the milk and cheese industry, ceramics and sanitation industries, chemical and pharmaceutical industries, car and related component manufacturers, foundries, steelworks, electronic industries, electrical energy production plants , petrochemical industries, textile industries and tanneries, etc.

Water treatment equipment and systems are produced for:

- making water drinkable

- preparing water for bottling

- preparing water for the production of soft drinks, fruit juices, beer, etc.

- treating wastewater for all sorts of civil and industrial purposes

- sludge dehydrating stations

Della Toffola also designs and implements the revamping of existing industrial water treatment plants to adapt them to new functional or dimensional needs, which includes updating the technology involved and/or increasing their output.

The sections comprising the system are developed on the grounds of a dedicated, detailed project, then constructed and assembled at the company's plant. In addition to supplying the technology and systems, Della Toffola also provides its customers with a complete service that includes the preliminary feasibility study, installation and start-up, thorough training of the customer’s personnel, and the supply of all necessary documentation and certificates, as well as after-sales support and servicing.