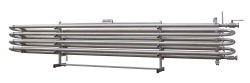

Temperature control systems

These systems are particularly suitable for lowering the temperature of crushed must, monitoring and maintaining the temperature during fermentation, checking and maintaining the ideal temperature of wines in storage, as well as lowering the temperature of wines as part of the tartaric stabilizing process.

These systems are designed and manufactured to the customer's specifications.