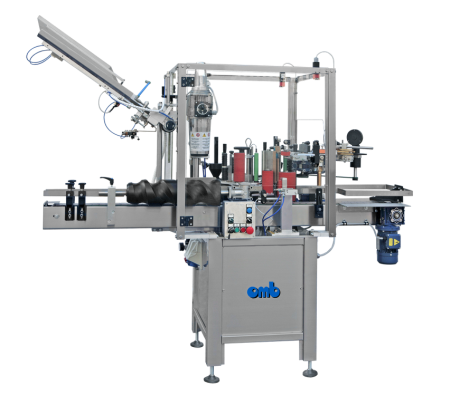

Beverage and wine label machine MOD. ET 800

Automatic linear label machine for attaching self-adhesive labels to cylindrical bottles or containers of wine, beverages or foodstuffs in general, consisting of: a body labelling station (with the opportunity for attaching a back label from the same roll); forward feed; fixed pick-up plate. The beverage and wine label machine is delivered ready for including in a bottling line and equipped for a given type of capsule and bottle or cylindrical container.

Made entirely of stainless steel, it is solid and strong and based on an advanced technology, achieving a high output. Designed for maximum operator safety and ease of use, the beverage and wine label machine is quick to adjust and complete with safety shields. At the customer's request, it can be adapted for use with stiff paper or cardboard containers, and cardboard boxes.

Working direction from left to right

Output: 1200 bottles per hour

EQUIPMENT:

- station for back label

- station for DOCG round label or neck band

- turret station for transferring and attaching biadhesive DOCG neck bands or “I”-shaped labels

- capsule distributor

- head handling unit

Made entirely of stainless steel, it is solid and strong and based on an advanced technology, achieving a high output. Designed for maximum operator safety and ease of use, the beverage and wine label machine is quick to adjust and complete with safety shields. At the customer's request, it can be adapted for use with stiff paper or cardboard containers, and cardboard boxes.

Working direction from left to right

Output: 1200 bottles per hour

EQUIPMENT:

- station for back label

- station for DOCG round label or neck band

- turret station for transferring and attaching biadhesive DOCG neck bands or “I”-shaped labels

- capsule distributor

- head handling unit

MADE by OMB ITALIA Srl